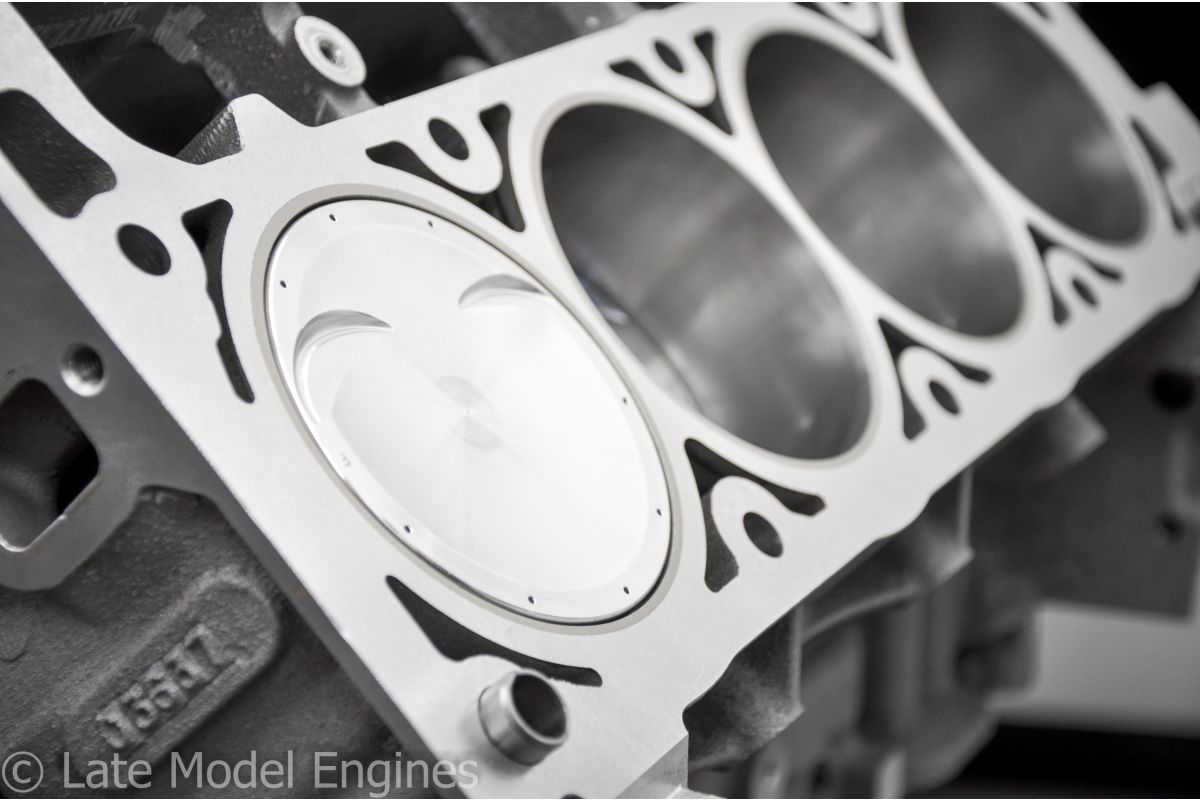

GM LSA 416" Short Block

Available Qty: 0

$10,749.00Creating a more stable platform while making alot more reliable power on your Cadillac cruiser is made possible by using custom forged 4.070" Wiseco pistons that feature gas Nitrided rings, Callies Compstar Extreme H-beam 6.125" rods, and Manley's 4" stroke forged crankshaft. This more rigid reciprocating end will keep everything in check with your 1.9L LSA blower, 2650, or even with a significant shot of N2O into the 10:1 chambers.

| Displacement: | 416" | Bore: | 4.070" |

| Proven Power Rating: | 1200 RWHP | Stroke: | 4.000" |

| Compression Ratio: | 9.5 - 10:1 | Rod Length | 6.125" |

| Cylinder Head Compatibility: | LS3, LSA, LS9 | Oil System Type: | Wet Sump |

| Block: | GM LSA 6.2L Aluminum |

| Crankshaft: | Manley 4.0" Forged crank/ LME Blueprinting Process |

| Connecting Rods: | Callies Compstar Extreme H-Beam w/ARP Ultra 7/16" Bolts |

| Pistons: |

Wiseco LS Forged Boost Pistons |

| Wrist Pins: | H-13 Heavy Wall .185" |

| Ring Pack: | Wiseco Gas Nitrided Rings |

| Bearings: | Clevite H Series Main & Rods |

| Main Studs: | ARP |

***CORE EXCHANGE SHIPPING: LME is happy to assist you in shipping your block and crankshaft cores to help you save money. Exchanging your block & crank cores helps reduce the overall engine build cost without sacrificing quality. We can have your existing shortblock picked up at a location convenient for you.

LME Standard Shortblock Blueprinting Process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|