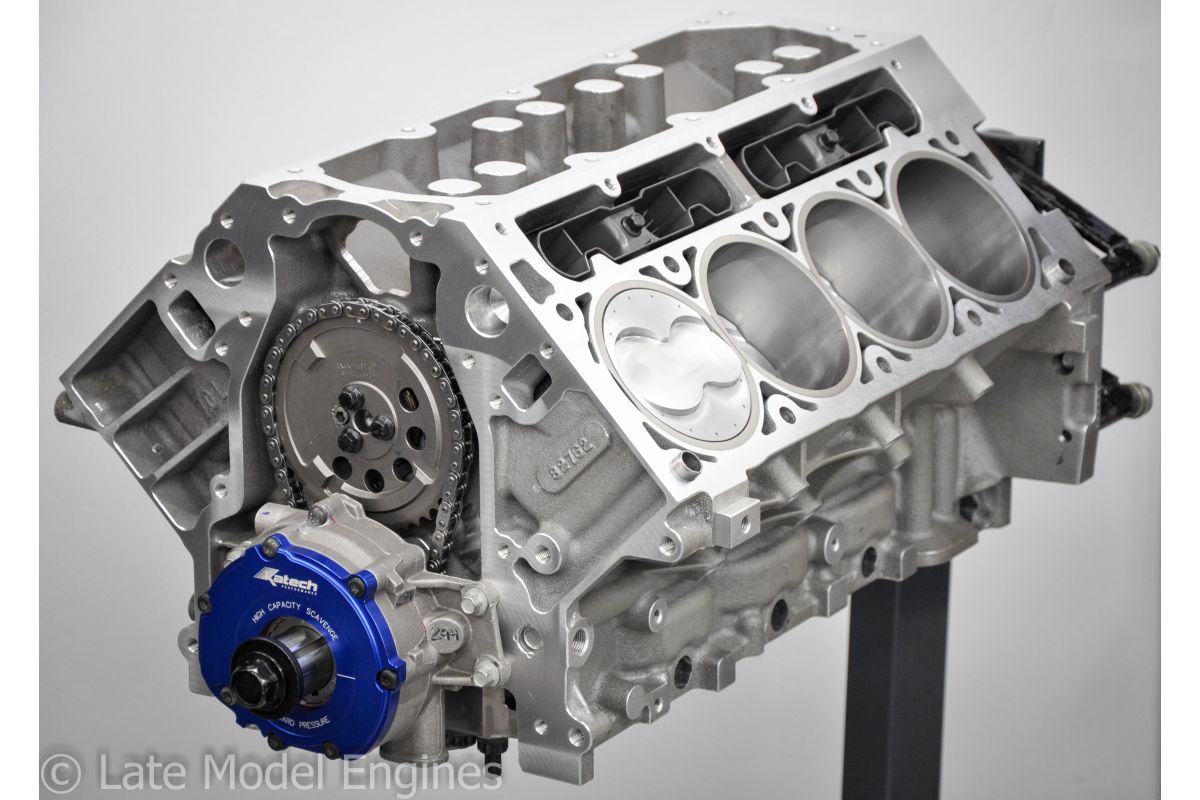

LS7 440" N/A - Nitrous Short Block

Available Qty: 0

$8,200.00With a 4.130" bore and 4.125" stroke crank, this stout 440" unit will shake the pavement. Cruise the streets with an attitude and tear up the track with a shot of N2O reliably using custom forged Diamond pistons, Callies Compstar crank and rods.

| Displacement: | 440" | Bore: | 4.130" |

| Proven Power Rating: | 850 RWHP w/ Nitrous | Stroke: | 4.125" |

| Compression Ratio: | 12:1 w/ 70cc Chamber | Rod Length | 6.125" |

| Cylinder Head Compatibility: | LS7 | Oil System Type: | Wet or Dry Sump |

| Block: | Choose From Options |

| Crankshaft: | Callies 4340 Compstar w/ LME Blueprinting Process |

| Connecting Rods: | Callies Compstar Xtreme H-Beam w/ ARP 2000 7/16" Bolts |

| Pistons: | Custom Diamond Pistons |

| Wrist Pins: | Tool Steel |

| Ring Pack: | NPR Stainless Top (for high heat applications) Napier Second, 3mm Oil |

| Bearings: | Clevite H-Series Mains & Rods, DuraBond One Piece Cam Bearings |

| Main Studs: | ARP |

******ATTENTION******* GM HAS DISCONTINUED THE LS7 BLOCK. LME NO LONGER OFFERS NEW LS7 BLOCKS. PLEASE CHOOSE FROM THE OPTIONS WE PROVIDE, YOUR LS7 BLOCK, LSR OR DART BLOCK.

LME Standard Shortblock Blueprinting Process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|