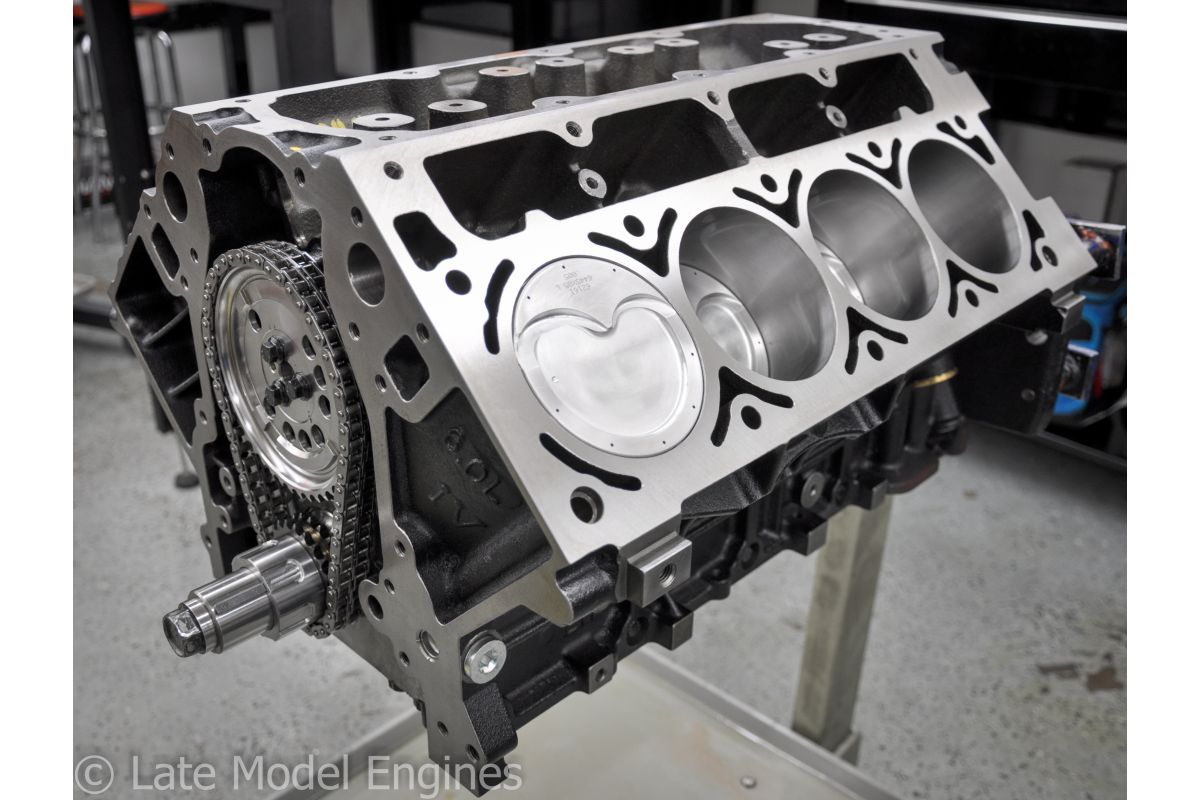

LS1 402" Force Induction Iron Short Block

Available Qty: 0

$8,750.00Suited for your supercharged C5, wicked turboed WS6, or even rowdy work truck, this stringent power plant will handle more than moderate boost while maintaining street reliability. Composed of fine offerings from Callies Compaster, the 4.000" stroke crank furnished with 6.125" rods adorn forged Wiseco pistons that fill the 4.000" cylinder bores.

| Displacement: | 402" | Bore: | 4.005" |

| Proven Power Rating: | 1000 RWHP | Stroke: | 4.000" |

| Compression Ratio: |

10:1 w/ -15cc Piston and 67cc Chamber 9.5:1 w/ -20cc Piston and 67cc Chamber |

Rod Length | 6.125" |

| Cylinder Head Compatibility: | LS1, LS2, LS3, LSA, LS9 | Oil System Type: | Wet Sump |

| Block: | GM LS1 6.0L Iron |

| Crankshaft: | Callies Compstar w/ LME Blueprinting Process |

| Connecting Rods: | Callies Compstar H-Beam w/ ARP 2000 7/16" Bolts |

| Pistons: | Wiseco Custom Forged FI (.300" material above top ring land) |

| Wrist Pins: | Wiseco Standard Pins |

| Ring Pack: | NPR Stainless Top (for high heat applications) Napier Second, 3mm Oil |

| Bearings: | Clevite H Series Mains & Rods, Dura Bond One Piece Cam Bearings |

| Main Studs: | ARP |

***CORE EXCHANGE SHIPPING: LME is happy to assist you in shipping your block and crankshaft cores to help you save money. Exchanging your block & crank cores helps reduce the overall engine build cost without sacrificing quality. We can have your existing shortblock picked up at a location convenient for you.

LME Standard Shortblock Blueprinting Process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|