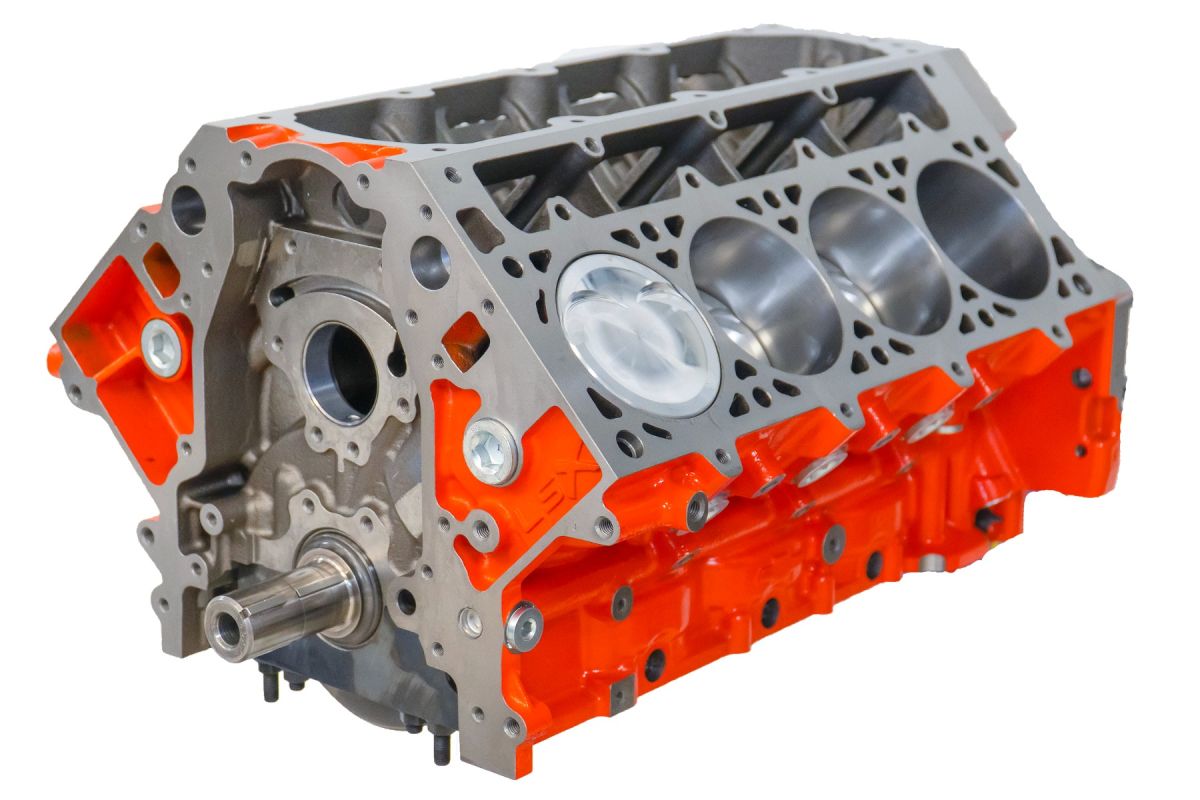

427" LSX 2500hp Short Block

Available Qty: 0

$18,399.00This short block is the heart of the proven combination that gives you 2000+ horsepower at your disposal. The solid foundation starts with your choice of blocks; the vigorous LS-Next from Dart or direct from GM, the mighty LSX. Both feature remarkable improvements to the oiling system and are cast with exceptional materials. Handling the top end are provisions for 6-bolt head configuration with 1/2" studs, this recourse makes cylinder head gasket and head lift issues a thing of the past. LMEs custom forged 4.125" piston from DIAMOND is designed to handle the astounding heat and cylinder pressures today's boosted street machines produce. Callies Billet 4.000" stroke crank with, 6.125" Ultra rods, and .250" wall heavy duty pins conclude the proven rotating construction making this the ultimate base for street car dominance.

| Displacement: | 427" | Bore: | 4.125" |

| Proven Power Rating: | 2000+RWHP | Stroke: | 4.000" |

| Compression Ratio: | 10:1 | Rod Length | 6.125" |

| Cylinder Head Compatibility: | Any LS Configuration | Oil System Type: | Wet Sup or Dry Sump |

| Block: | GM LSX |

| Crankshaft: | Callies EN30B Billet 8 Counterweight w/ LME Blueprinting Process |

| Connecting Rods: | Dyres 300M Billet H-Beam w/ ARP 7/16" "D" Bolt |

| Pistons: | Diamond Custom Forged FI w/Gas Ports (.300" material above top ring land) |

| Wrist Pins: | TP1 Tool Steel Heavy Wall .210" |

| Ring Pack: | Total Seal AP Stainless Top (for high heat applications) AP Stainless Napier Second, 3mm Oil |

| Bearings: | Clevite H Series Main & Rods |

| Main Studs: | ARP |

LME Standard Shortblock Blueprinting Process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|